AC/DC Power Supplies

AC/DC Power Supply Test Systems

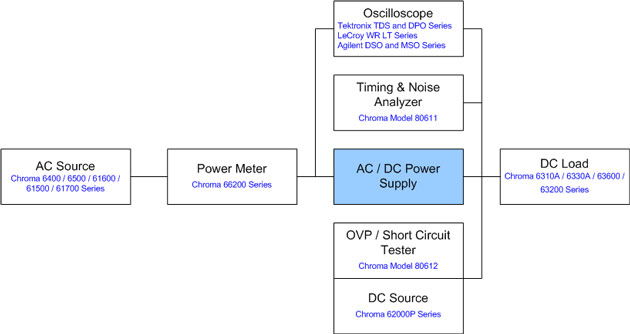

Chroma’s C8000 Automated Test Systems are the ultimate solution for AC/DC Power Supply testing, common power supplies are Linear, Switch Mode and Programmable Power Supplies, plus AC Adapters. Our test systems are application oriented making them the most cost effective for both high speed production applications as well as design verification.

Product Choices

- AC Power Sources: Chroma 6400/6500/61500/61600/61700 Series

- DC Power Supply: Chroma 62000P/62000B/62000H

- DC Loads: Chroma 6310A/63200/6300/6330A Series

- Power Meters: Chroma 66200 Series

- Timing & Noise Analyzer: Chroma 6011/80611 Series + 80611N

- OVP/Short Ciurcuit: Chroma 80612 Series

- Oscilloscope: Tektronix TDS, DPO Series; Lecroy WR LT Series, Agilent DSO, MSO Series

To meet the power supply test requirements of today’s environment, the Model 8000 comes standard with an off-the-shelf pre-written test item library covering most industry standard power supply tests. The comprehensive test items covers 7 categories of power supply testing requirements, which includes output performance, input characteristics, regulation tests, timing and transient, and protection tests. Users may also create new test items by using a special test item editing function. This gives users the capability to expand the test library unlimitedly.

Customized Test Fixtures

The test fixture, a device that interfaces between the ATS and UUT, is necessary for automated testing. Due to different form factors and various connector types, it is impossible to find an off the shelf test fixture that can fit all test requirements. The Chroma 8000 ATS support team not only helps plan and develop the ATS, but the also provide their expertise to tailor a test fixture to the customer’s needs.

Input/Ouput Characteristics

| Maximum Input Voltage | Maximum Input power | Maximum Input Current | Maximum Output Voltage | Maximum Output Power | Maximum Output Current | Maximum Number of Outputs | |

| AC/DC | 500 VAC | 54 KVA | 432 A | 600 VDC | 78 KW | 5,000 A | 32 |

Comprehensive Test Items

The Model 8000 automatic power supply test system comes standard with an off-the-shelf test item library covering most industry standard power supply tests. Unlike traditional ATE software, users do not need to have programming language background to create new test items. Instead the Model 8000 allow users to use pre-compiled test items and to simplify defining test conditions and specifications.

The comprehensive test items cover 7 categories of power supply testing requirements. "Output Performance" checks the general performances of the UUT. "Input Characteristic" verifies the input parameters of a power supply. "Regulation" tests the stability of the UUT under varying line-in and loading changes. "Timing & Transienst"measures the transient state during turn-on, turn-off or when events occurred. "Protection Tests" triggers the protection circuit of the power supply. Finally, the "Special Test" and the "Special Features" provides means to test the most sophisticated power supplies when unique test routines are needed.

Output Performances

Input Characteristics

|

Regulation Tests

Timing & Transient

Protection Tests

|

Special Tests

Special Features

|

* These test items need to be created by users by using test item editor due to the variety of the UUTs. And unlimited customized or user defined test items are allowed.

Basic System Layout

Expert Information

Our experienced ATS engineers can help you select the right system for your application. Contact Chroma Systems Solutions today!

Join our e-mailing list to get new product releases, news, and our quarterly report.

DC Electronic Loads

- Modular 63600 DC Loads with Constant Impedance Mode

Chroma's 63600 Series DC Electronic Loads are designed for testing multi-output AC/DC power supplies, DC/DC converters, chargers, batteries, adapters, and power electronic components. Excellent for research, development, production, and incoming inspection applications.

Digital Power Meters

- Meets Energy Star Measuring Requirements

The 66201 Digital Power Meter is packaged in a 2U high, half rack enclosure suitable for bench top or system integration and includes simple measurement functions designed for low power applications (maximum current 2A).

Model 66202 Digital Power Meter includes a 2-shunt design to provide highly accurate readings for both low and high current measurements. In addition to the parameters measured by Model 66201, the 66202 includes Inrush current, Total Harmonic Distortion of V/I, and Energy measurements. With these practical functions, The Model 66202 is suitable for the most demanding of R&D and quality control departments.